The entire idea behind improving one’s business seems logical, it seems quite intuitive, but that’s just on paper, it is quite different when it comes to reality. The entire idea behind “lean” is indeed very simple, you just have to optimize various aspects of your business, remove all of the waste and useless aspects of it, do the best that you can to make it as straight-forward as possible in order to make it as efficient as possible. Yet in order to do all of these things, you must know what you are doing, you must have some theoretical basis behind all of your actions. You must have a structured plan of actions. When such improvements become continuous, they are referred to as Kaizen. Let’s talk about Kaizen and the here main things you should know about it.

You have to adopt a certain attitude, a specific mentality

Some people think of the idea of implementation of positive changes into their business as something rather shortterm oriented, just as an event. You just have to throw out the garbage and that’s all. We hope you understand that it’s not an event, it is about a continuous process. Every continuous process requires lots of commitment in order to keep it going. Lack of commitment will inevitably cause you to doubt your strategy and may even force you to abandon it completely. Thus, in order to be effective at business optimization – you have to commit to it.

It reaches its peak productive when an entire company adopts is

You should be committed to making serious changes, sure, but they won’t matter if your coworkers and employees won’t share your vision for the future of your company. Also, you must make sure that there won’t be any strategic discord in the ranks of your company. All the departments must have a certain mindset, they must be aware of the goals you have in mind. Sure, you cannot truly turn all of your employees into a bunch of your own clones, but they must all be on the same page.

It is the ultimate tool of optimization

Strategic discord is the death of the Lean process. Kaizen is impossible if your team isn’t working together. Thus, in order to make your company productive – all of the departments and their employees must know their jobs and what they are allowed and disallowed to do.

Here’s how the Kaizen goes: You must first identify the problems in the workflow, then you have to plan out the ways to fix the problems and make some room for improvements, then you must implement your plan, and then you must review all of the work that was done. Then repeat the entire process all over again.

The ways of Lean Implementation

That was just the theoretic part of the things you need to know about the magic of the Lean process, but what are the actual ways in which you can implement it in your company?

Kanban

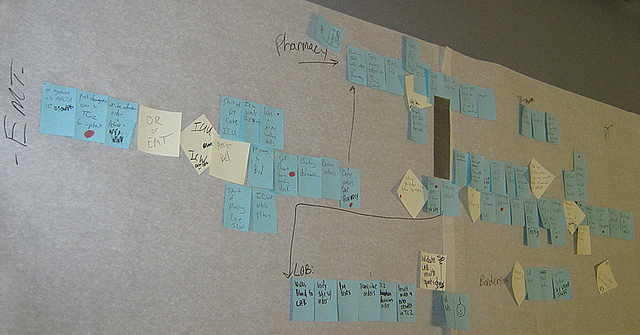

Kanban allows you to visualize all the work that was made during the lean process. It will allow you to identify problems, find opportunities, establish a plan, and then track all of the progress that was made during the process of following your plan.

If you are interested in the implementation of Kanban, then be sure to check out Kanban Roadmap.

Limits of WIP

WIP stands for work in progress and it should have certain limits in place. Having WIP limits is one of the aspects of the lean process.

It is quite simple, by using Kanban, you can track your WIP limits by the number of cards that are being worked on. There’s also the LeanKit, which will notify you when will reach WIP limits.

It is basically an optimized system of setting deadlines, statuses, priorities in order to optimize the workflow. It also helps a team to have a common mindset and a goal.