What is lean thinking? It is a business process improvement strategy that has become popular as a result of the huge improvements made by Japanese companies such as Toyota. Lean Thinking is also the title of a popular book on the subject by James P. Womack and Daniel T. Jones.

The history of Lean Thinking

After the second world war, the japanese economy was in ruins. The American economy on the other hand was booming. As a result, of this a number of leading quality management gurus like Deming and Juran travelled to Japan to share their teachings. The Japanese took these principles to heart and applied them rigourously. By the 1970s and 1980s, the quality of automobiles coming out of Japan was far superior to American vehicles. Toyota in particular lead the way, gaining an outstanding reputation for reliability.

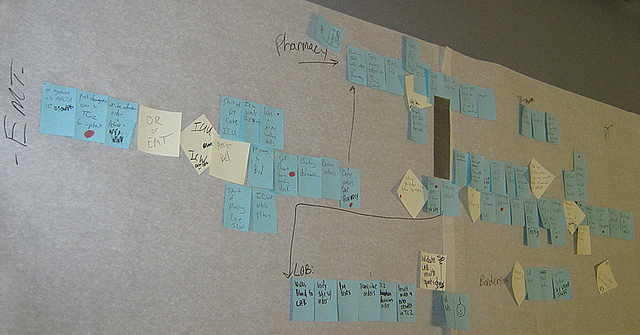

In an attempt to close the gap to the Japanese automakers, there has been a global resurgence of interest in Lean methods and techniques. This growth has spread outside the automotive industry into other manufacturing sectors as well as into transactional environments and even healthcare.

What is Lean Thinking: The Manufacturing Improvement Principle

When asked the question, “what is lean thinking?” many people tend to think of the many lean tools and techniques they have heard of. These include 5S, poka yoke, Takt time and pull. However, these are just methods that have been developed to help achieve a number of fundamental lean principles. These are the principles of lean manufacturing.

The first of these principles is to eliminate waste. Waste is defined as anything for which the customer is not willing to pay. This could be additional features that the customer does not value, or it could be maintaining manufacturing tolerance more tightly than is required. If it consumes resource within the company (materials, labour, time) and the customer will not pay more for it, then this is a waste. By removing this waste from the product or process, the business can save money and improve. This is known as becoming leaner.

What Is Lean Thinking: The Book

Lean Thinking has been an enormous influence on my business thinking. It shows you how you can fundamentally transform your business.

~ Sir Terry Leahy, Chairman and Chief Executive, Tesco PLC

The tagline for the book Lean Thinking

is “Banish Waste and Create Wealth in Your Corporation”. It was originally published in 1996 and an updated and revised edition was released in 2003.

The book is divided into four sections. Part 1 covers Lean Principles. “Lean thinking can be summarized in five principles: precisely specify value by specific product, identify the value stream for each product, make value flow without interruptions, let the customer pull value from the producer, and pursue perfection”.

Part 2 is focused on putting the Lean Principles from part 1 into action, or making the Lean Leap. “Concentrate on managing the value stream for the specific service or good, eliminate organizational barriers by creating a lean enterprise, relocate and right-size tools, and apply the full complement of lean techniques so that value can flow continuously”.

Part 3 extends the principles already covered to the extended value stream to optimise value for the end customer while “minimising time, cost and errors” for all companies involved.

Part 4 is the epilogue where the latest advancements in lean thinking are added bringing the story right up to date.

About the Authors

James P. Womack is the founder and senior advisor of the Lean Enterprise Institute.

Daniel T. Jones is the founder and chairman of the Lean Enterprise Academy in the United Kingdom.

Other notable publications by Womack and Jones include The Machine That Changed the World and Lean Solutions