In a previous post, we explored thefactors that affect the success of a six sigma programme within a company. So in this post we can now consider how six sigma is applied in different types of industry.

Typically, statistical process control has been widely used in manufacturing companies, but it is not common in service sectors. This has led to a belief that six sigma is not relevant for service based organisations. This fact was highlighted by a particular response the author received when researching how six sigma is implemented in various companies:

“Further to your letter regarding Six Sigma etc dated 30th Jan…In Europe we are a sales and marketing organisation and have no experience in relation to Six Sigma or other manufacturing related quality management systems.”

Is this an indication that six sigma is only fit for use in manufacturing companies? Or is it simply an anomaly? If the former is true, then why is six sigma only suitable for manufacturing processes? If the latter is true, then why is there such a common belief that six sigma is only a manufacturing quality management system? This post will consider the answers to these questions.

When investigating this subject it is useful to have a clear distinction between the terms manufacturing and service. Manufacturing is used to describe the process of designing, developing and building a product for sale to a customer. It is an engineering process. Service operations, on the other hand, are best thought of as transactional processes. A transactional process is defined as:

“one that is outside the scope of the normal manufacture of a product and involves activities in which an item of work is processed, transacted or completed.”

~ (NICHOLS, 2006)

Examples include issuing an invoice, dispatching an item for delivery, logging a customer complaint and ordering stock. It is also important to note that all manufacturing organisations rely on some service processes in departments such as sales, HR and accounts. A service company does not have any manufacturing processes.

The literature available on the subject (PANDE et al., 2000; DOES et al., 2002; NICHOLS, 2006) suggests that six sigma is equally as important, and feasible to implement in service based operations as it is in manufacturing.

“Six Sigma’s general approach to problem solving and the associated tools are applicable with only minor adjustments and can be used with benefit in both manufacturing and non manufacturing.”

~ (DOES et al., 2002)

So why is there a misconception that this is not the case? It is mainly due to the fact that manufacturing has long been subjected to continuous improvement initiatives. The people involved see six sigma as a trendy name for something they have already been doing for a long time. In service departments and businesses however, there has never been the same kind of movement. Services are usually provided on a departmental basis and as a result tend to grow independently despite connections with other functions.

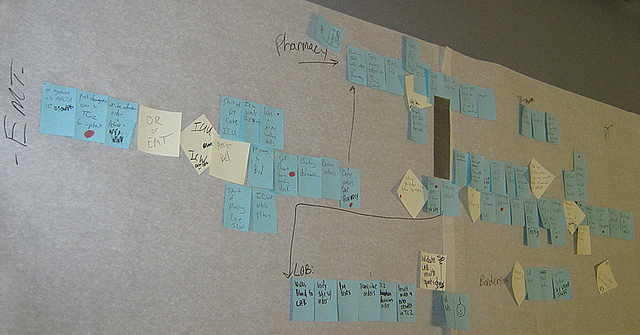

This problem has been compounded by the fact that many departments are not located in the same place, or even the same country. Outsourcing of call centres to low labour-cost countries springs to mind as the obvious example. This makes it difficult to follow a process from start to finish, resulting in many inefficiencies and interdepartmental issues creeping into the system. Basically, service personnel are not trained to think of their work as a process in the same way manufacturers are.

Six Sigma DMAIC in a Transactional Process

All service tasks can be thought of as a process with inputs and outputs. In a service environment this might mean reducing billing errors, reducing the time a customer is on-hold at a call centre, or increasing the speed with which applications are processed. These are obviously just a few examples. However, the DMAIC process can be used to fix problems in transactional processes just as well as in a manufacturing process.

- Define the problem.

- Measure the current level of performance.

- Analyse the inputs and process variables to identify which are affecting the output.

- Improve the output by tweaking the critical few variables.

- Control the process to prevent the problem recurring.

In reality, there is a cultural change required for employees to see the work as a process. This is one of the main implementation problems to be overcome before six sigma can be successfully implemented in a service based business.

“Once a process view is accepted by the organisation, it is easier to focus on what the key deliverables are from any given process and the process itself can be designed to deliver to the customer’s expectations.”

~ (NICHOLS, 2006)

Some of the literature even goes as far as to say that six sigma will have more of an impact in service sectors than it has already achieved in manufacturing.

“It’s likely that it is…service activities that will benefit most from the Six Sigma approach.”

~ (PANDE et al., 2000)

“Six Sigma is now increasingly applied to a wide variety of non-manufacturing operations also. This is an important development - there are potentially more benefits to be achieved in those areas than in traditional manufacturing.”

~ (DOES et al., 2002)

The reason that six sigma is likely to have a greater impact in service based operations is that it is the first real approach that has been used to improve transactional processes, whereas manufacturing has benefited from decades of continuous improvement efforts.

References

- DOES, R. VAN DEN HEUVEL, E. DE MAST, J. & BISGAARD, S. (2002). Comparing Nonmanufacturing with Traditional Applications of Six Sigma. Quality Engineering. Vol. 15. No. 1. pp. 177-182.

- NICHOLS, M. (2006). Quality Tools in a Service Environment. ASQ Six Sigma Forum Maga- zine. Vol. 6. No. 1. pp. 12-13.

- PANDE, P. NEUMAN, R. & CAVANAGH, R. (2000). The Six Sigma Way - How GE, Motorola, and Other Top Companies Are Honing Their Performance. New York: McGraw Hill.