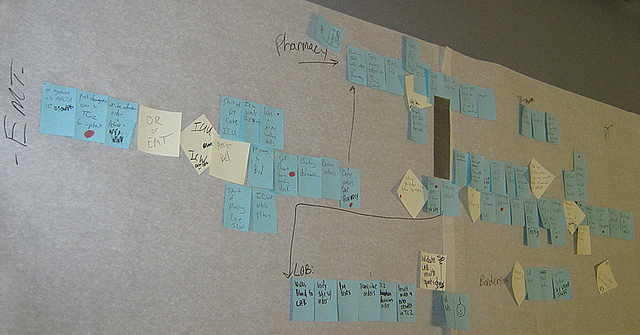

Defines targets/goal Safety, Delivery, Quality, Cost

The first objective of a board is to display the important metrics for a particular work area. These could be measurements of Safety performance such as number of accident free days. Quality indicators might include scrap %, number of defects or PPM. Delivery metrics are usually based around customer delivery performance. Finally, cost indicators can include productivity ratio and inventory turns.

The point of having these targets or goals displayed on a visual management board is that it makes it very clear to all employees what they are working to achieve. The board provides clarity for all people at all levels from the operator on a cell to the plant manager.

Makes current condition clear to all

Another purpose of the visual management board is to display the current status of the process. How is the process currently performing? Is it meeting target or not? Is it trending upwards or downwards, or is it stable? By making the current status of the process clear to all involved, it becomes easy to identify where the problems are. Out of standard conditions such as a line stoppage should be highlighted by a visual control. This is an indicator for the relevant individuals such as team leaders and supervisors to react and if necessary stop the process to initiate a countermeasure.

Shows a plan (PDCA)

If a process is not meeting the required level of performance as specified in the targets / goals, then it is necessary to display an action plan. This should define what the problem is, what the next steps are to try and fix the problem, who is responsible for completing these actions and when they will be done. The last thing that should be included on the plan, but is often missed by many, is how the team will confirm that the action has had the desired impact. How will they verify that the root cause was identified and prevented from recurring. The answer will obviously be different depending on the process and the problem.

Supports dialogue at all levels

The final purpose of a visual management board is to facilitate discussion at all levels of the team. The metrics on the board, the current level of performance, the problems experienced and the subsequent action plans put in place should serve as a focus point for managers and team members alike to meet and discuss how they can continuously improve the process day-by-day.

Photo Credit: cc Phil Manker