The Definition of the Lean Process

The lean process is one of the most important aspects of any business. It is the process during which you optimize your business, your production, remove all the things that are unnecessary or even harmful to your company and thus, lower your profit. It is commonly referred to as “lean”. A very big part of this process is played by the optimization of a business so that it will suit all of the needs and desires of your customers. The more effort and time you put in the lean process – the less waste-producing will your business be, the more satisfied will your customers be with your products and services.

Getting Started

This sounds all well and good, but how can one start the lean process? What should be done? What is the first step one must take in order to optimize their business? Well, it will require lots of effort and time, and most importantly, lots of commitment. This commitment should be displayed not only by you but your employees as well. However, the lean process is not something new to the market and the science of business optimization, there are some wellestablished lean methods that business use, here are some of them:

- Adoption of a basic system for manufacturing.

- Adoption of a strategy for continuous development.

- Adoption of metrics in order to track your company’s progress.

Simple Manufacturing

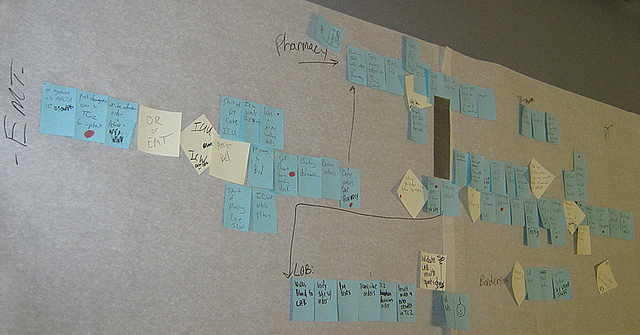

As the name suggests, it is quite simple. This method uses a pull-system in order to provide customers with goods and needs they require. Of course, pull-systems are quite widespread, one of the most popular ways of their implementation is called Kanban.

Kanban utilizes visual cards to conduct the production of goods depending on the wishes and desires of a customer base.

- Every product (or rather their packaging) has a Kanban card on it. These cards are used in order to identify the list and quantity of goods that were ordered by a customer.

- A worker must then order parts according to a card. It is then sent to a department which is in charge of purchases.

- Then, a department gives all the parts back to the workers. They can only do according to the Kanban cards, no other parts and supplies can be sent without a card.

This will allow a business to:

- Become more eco-friendly

- Optimize the workspace

- Become more productive

- Optimize the workflow

Commit to Constant Improvements

Just as with any other aspect of the business, you must be able to improve it and adapt it. Constant improvement is known as Kaizen.

In order to make sure that you are constantly improving your business, you must:

- Be open to criticism

- Look back on your achievements and notify your team about the positive changes that have been made after the adoption of Kaizen.

- Show that you trust your employees, let them speak.

Count Your Steps

One of the most important aspects of becoming better is to know what made you better.

SPC (Statistical Process Control) allows business owners to track the various process by using special metrics. SPC’s are commonly used in the form of charts.

OEE (Overall Equipment Effectiveness) revolves around three important things: whether or not your equipment is available, how good is its performance, the quality of the products that it produces.

Tools of Leaning

One of the easiest ways to optimize a business is to use 5S.

Here’s what it does:

- Optimizes the workplace.

- Organizes the work areas

- Motivates employees to help with the optimization and organization of their workplace.

- Documents all of the positive changes that were made.

- Constantly repeats all of the tasks above.